Services

Overview

Premium Transmission has been offering engineering excellence and expertise in the fields of design & manufacturing of gearboxes, geared motors and fluid couplings for various applications across the industry spectrum over past 6 decades.

Premium Care, Bhubaneswar was established in 2019 in association with Premium Transmission to provide a one stop solution for overhauling & reconditioning of any make of Gearboxes, Geared Motors & Fluid Couplings.

We have state of the art facilities along with the technological know-how for overhauling and reconditioning of gearboxes, geared motors and fluid couplings. Our well-trained, highly experienced & committed service engineers having a thorough knowledge of the standards and specifications with the right expertise of tools to address every aspect of refurbishment right from diagnostic work to the final adjustments. With the correct knowledge of reinstallation of components, we have proven our experience of critical application gearbox, geared motor & fluid coupling refurbishment, which allows us to repair or do reverse engineering and remanufacture the components for reuse.

Services

Services

- Drop in & Retrofit of any make

- Overhauling & Reconditioning of any make

- Spares Development through Reverse Engineering

- Casing Bore Repairing

- Onsite Reverse Engineering using 3D Scanner

- Comprehensive Health Check Up

- Onsite Repair & Maintenance

- Installation & Commissioning

Key Objectives

Key Objectives

Salvage Life of Aging Products

Improve Reliability by enhancing Ratings

Improve Overall Efficiency

Overcome Capital Budget Constraints

Reduce Dependency on OEMs

Why Choose Us

Why Choose Us

-

Well Equipped Facility

-

Experienced & Trained Service Engineers

-

Quick Response Time

-

Product Pick Up & Drop Facility

-

Quick Turnaround Time

-

Competitive Price

-

End to End Solution

-

Reverse Engineering Facility

-

Casing Repairing Facility

-

Warranty on Replaced Spares & Service

Process Flow

Process Flow

-

Product Receipt & Tagging

-

Disassembly & Cleaning

-

Quality Inspection

-

Inspection Report & BOM Sharing

-

Reverse Engineering

-

Spares Receipt & Quality Inspection

-

Finalization of Spares & Service Order

-

Spares & Service Quotation Sharing

-

Feasibility Check by R&D

-

Development of Drawings

-

Final Assembly

-

No Load Testing

-

Customer Clearance

-

Painting, Packing & Despatch

-

Product Receipt & Tagging

-

Disassembly & Cleaning

-

Quality Inspection

-

Inspection Report & BOM Sharing

-

Reverse Engineering

-

Development of Drawings

-

Feasibility Check by R&D

-

Spares & Service Quotation Sharing

-

Finalization of Spares & Service Order

-

Spares Receipt & Quality Inspection

-

Final Assembly

-

No Load Testing

-

Customer Clearance

-

Painting, Packing & Despatch

Applications

Applications

- Palletizing Disc Gearbox

- Vibrating Screen Gearbox

- Torpedo Laddle Car Gearbox

- Sinter Breaker Gearbox

- Blast Furnace Tilting Gearbox

- Vertical Roller Mill Gearbox

- Ball Mill Gearbox

- Vertical Coal Mill Gearbox

- Bucket Wheel Drive Gearbox

- Slew Drive Gearbox

- Bucket Elevator Gearbox

- Precipitation Tank Gearbox

- Desilication Tank Gearbox

- Digestion Gearbox

- Ladle Transfer Trolley Gearbox

- Caster Segment Drive Gearbox

- Crane Duty Gearbox

- Cooling Tower Gearbox

- Uncoiler Gearbox

- Recoiler Gearbox

- Pusher Car Gearbox

- Kiln Drive Gearbox

- Cooler Drive Gearbox

- GEHO Pump Gearbox

- Roller Table Gearbox

- Pulper Gearbox

- Conveyor Gearbox

Credentials

Credentials

Agitator Application

Make: FLENDER | Model: B4SV15 | Motor: 75kW @1500 rpm

Work Done: Internal Gears, Bearings, Oil Seal & FLS replaced

BEFORE

BEFORE

AFTER

AFTER

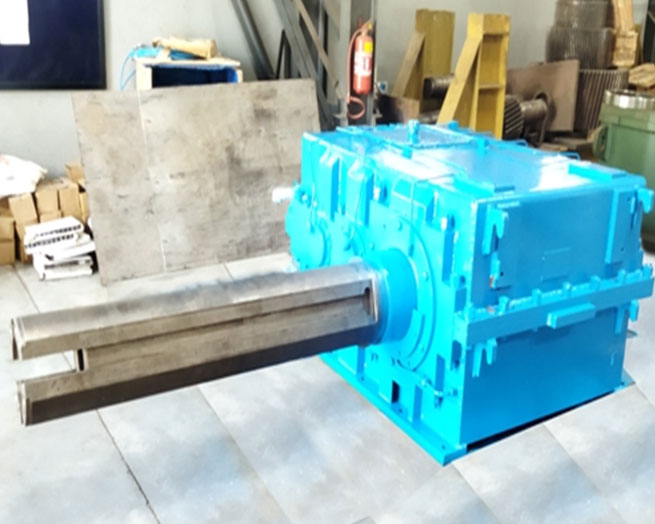

Uncoiler Application

Make: ESMECH | Model: Project 955 | Motor: 15kW @960 rpm

Work Done: Casing Repair, Internal Gears, Bearings, Oil Seal & Lubrication Pipelines replaced

BEFORE

BEFORE

AFTER

AFTER

Vibrating Screen Application

Make: TECNO | Model: WD 150 | Motor: 15kW @960 rpm

Work Done: Internal Gears, Bearings & Oil Seal replaced

BEFORE

BEFORE

AFTER

AFTER

Palletizing Disc Application

Make: FLENDER | Model: H3SH-13 | Motor: 220kW @ 1450 rpm

Work Done: Internal Gears, Bearings & Oil Seal replaced

BEFORE

BEFORE

AFTER

AFTER

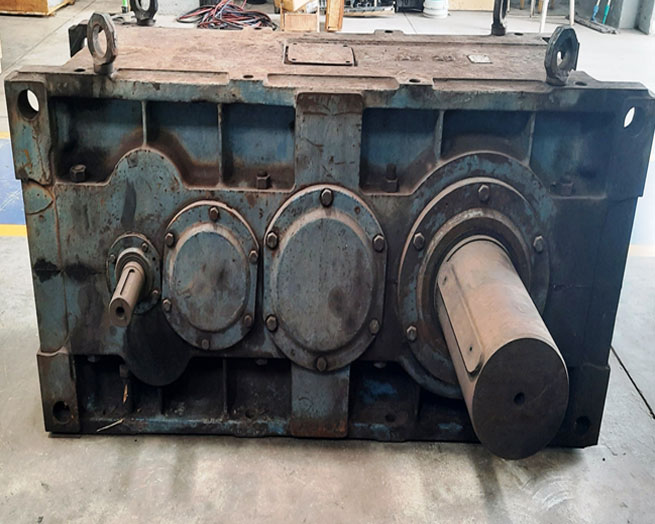

Kiln Drive Application

Make: ELECON | Model: PE 50 | Motor: 75kW @1000 rpm

Work Done: Casing repair, Internal Gears, Bearings & Oil Seal replaced

BEFORE

BEFORE

AFTER

AFTER

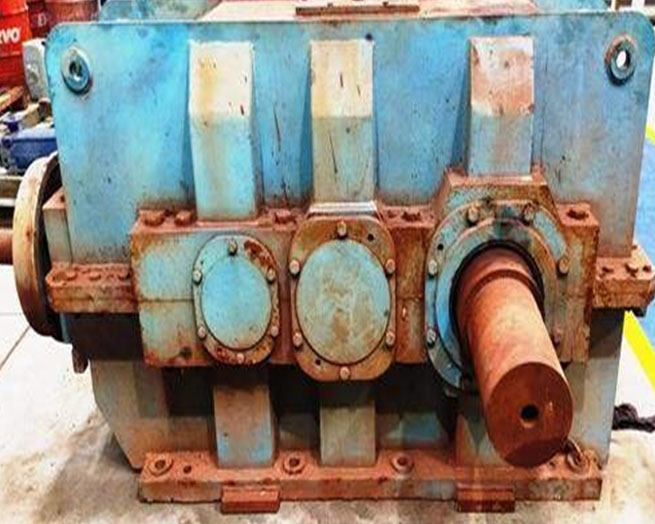

Conveyor Application

Make: ELECON | Model: KCN 560 | Motor: 860kW @1500 rpm

Work Done: Bevel Pair, Bearings & Oil Seal replaced

BEFORE

BEFORE

AFTER

AFTER

Geho Pump Application

Make: FLENDER | Model: H3SH 15 B | Motor: 760kW VFD Drive

Work Done: Bearings & Oil Seal replaced

BEFORE

BEFORE

AFTER

AFTER